Container Glass

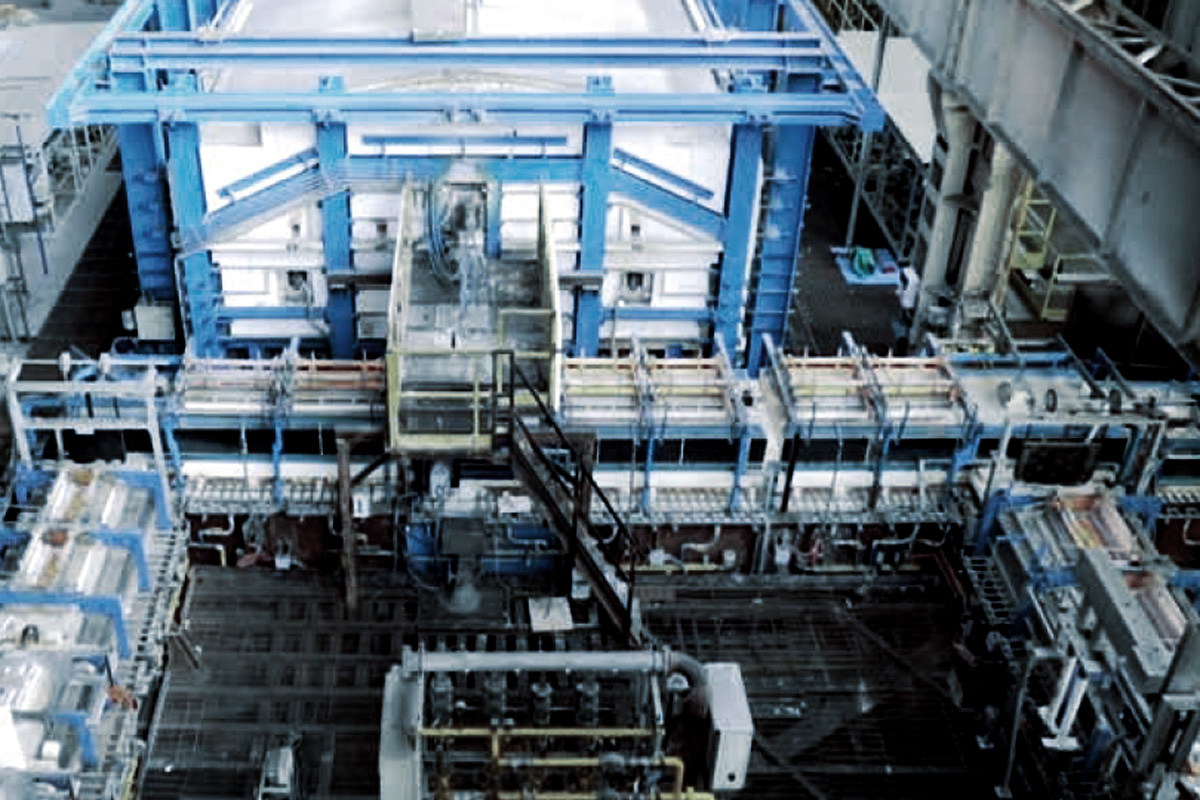

Whether you're making jars or bottles, you need a container glass furnace you can rely on to work non-stop without interrupting production. Even the slightest delay can have huge knock-on effects. That's why every SORG furnace is designed for performance and endurance – working 24/7 and producing up to 700 t/pd for up to 15 years – all backed by our whole of lifecycle support.

RETURN TO TOPFeatured Technology

SORG has risen to the challenges of the glass industry and developed an exciting new hybrid melting concept to ensure a much more sustainable future for our customers around the world.

Find Out More

Flexible and highly sophisticated with low operation costs, regenerative end-fired furnaces are very popular worldwide.

Find Out More

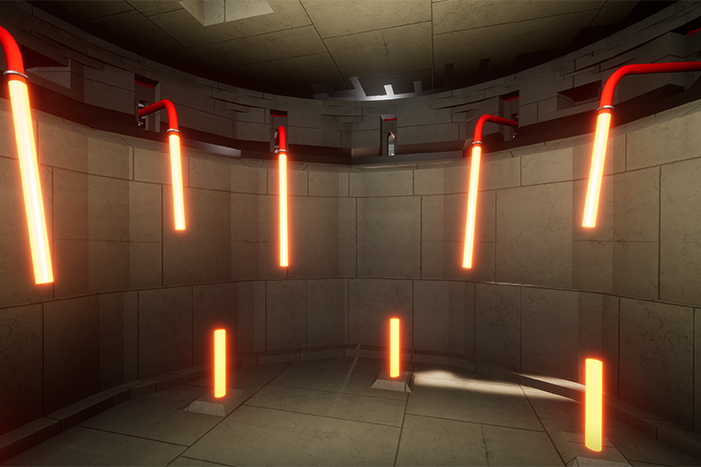

The SORG VSM® all‐electric furnace is a cold‐top, vertical melter, in which the processes of batch charging, melting, fining and refining all take place in a vertical direction.

Find Out More

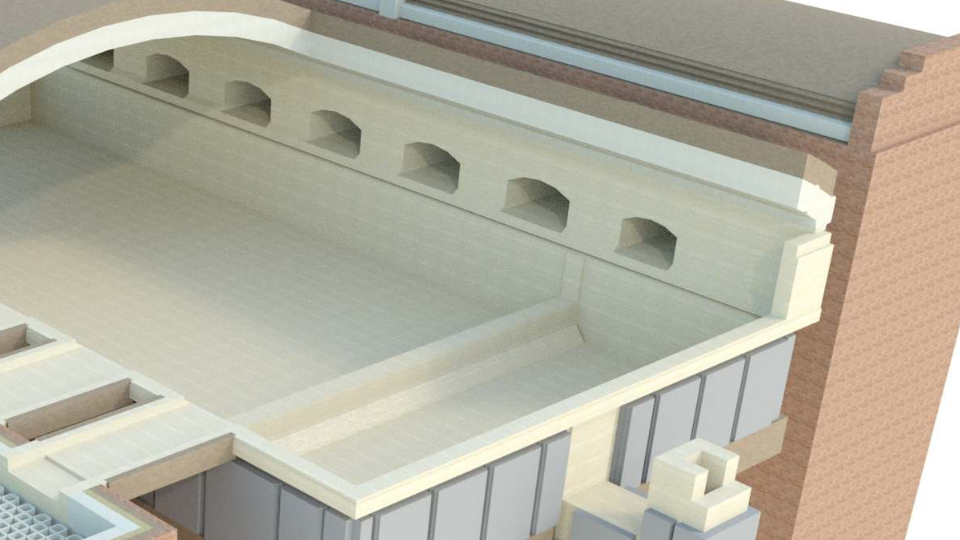

While end‐fired furnaces are commonly used for melting areas of up to 180 m2, regenerative cross‐fired furnaces are used for larger melting areas with very high tonnages. Today they are the main furnace type for the production of float glass, so they are also called float furnaces. The name of this furnace comes from its unique way of production, as the molten and fined glass are floated on a tin bath to improve its surface quality.

Find Out More

This furnace can be designed with either a single or a twin doghouse, located either on the rear wall of the tank or on the side.

Find Out More

This type of side‐fired furnace is similar to recuperative side‐fired furnaces but uses oxygen-fuel combustion for heating.

Find Out More

The innovative OxEcon® Melter incorporates conventional oxy‐fuel firing and combines it with the advantage of internal batch preheating to reduce energy consumption.

Find Out More

This furnace concept is primarily used for special glasses and small installations, with melting capacities of up to 45 t/24h.

Find Out More

The FlexMelter® is designed for continuous or discontinuous production of high-quality glass. When the furnace is not being pulled, it is not necessary to drain the glass.

Find Out More

The LoNOx® Melter is a special recuperative furnace developed to operate with very low NOx emission levels.

Find Out More